Tools Every Concrete Contractor Must Have

Posted On: 12/15/2021 | Posted by: DY Concrete Pumps

With the right concrete pouring equipment, you can get your project finished and move on to your next job in record time. From protective and site preparation gear to concrete pumps and finishing tools, there’s quite a bit of equipment to master before becoming a professional concrete contractor. Learn more about the tools and equipment used in concreting below.

Protective Gear

As you begin your project, it’s crucial that you have protective equipment for concrete work for your hands, feet and eyes. Concrete is a dangerous material that can be an abrasive irritant to your skin. Depending on its chemical composition, concrete can even cause chemical burns.

While working with concrete, always wear rubber work boots to protect your feet and alkali-resistant gloves to prevent burns from exposure to concrete over an extended period. Safety glasses and masks are also essential to protect your eyes and lungs from concrete dust and debris exposure. Read through the national standards on protective concrete gear to learn more about staying safe.

Site Preparation Materials

Setting up a well-prepared site is essential to ensuring your concrete has a solid foundation and a professional appearance. The following material and equipment can help you get your site prepared for the concrete pouring phase:

- Levels: Having a level sub-base and slab surface is the most critical element of site preparation. Laser levels are now the gold standard for site preparation. With the right level, you can ensure your readings are accurate and decrease the risk of human measuring error.

- Compactors: Compactors and tampers allow you to start your job right with a firm, solid stone base. If you’re using low slump concrete, you can use tampers to push the aggregate below the slab surface.

- Vapor barriers: While not all projects call for the use of vapor barriers, they can significantly improve the outcome of your project. By installing a vapor barrier before pouring concrete, you can prevent moisture from seeping into the concrete slab and ruining the finish.

Boom and Line Concrete Pumps

Concrete pumps are the most efficient and cost-effective tool for concrete pouring and placing on the market. With concrete pumps, you no longer have to manually mix and transfer materials, meaning you can minimize labor while improving employee safety conditions on your work site. There are two main types of concrete pumps:

Concrete Boom Pumps

Concrete boom pumps are used for residential and commercial construction sites and have become the industry standard for pumping efficiency. Truck-mounted boom pumps allow you to easily maneuver your concrete pump around the job site and move into hard-to-reach areas. Their potential for high-volume concrete pumping and accurate delivery makes boom concrete pumps the gold standard on many job sites.

Concrete boom pumps include:

- 57 meter 6 section RZ-fold (57X-6RZ)

- 57 meter 6 section RZ-fold (57S-6RZ)

- 52 meter 5 section RZ-fold (52X-5RZ)

- 48 meter 5 section RZ-fold (48X-5RZ)

- 43 meter 5 section RZ-fold (43X-5RZ)

- 42 meter 5 section RZ-fold (42X-5RZ)

- 40 meter 5 section ZR-fold (40X-5ZR)

- 38 meter 5 section ZR-fold (38X-5ZR)

- 37 meter 4 section roll-fold (37X-4R)

- 33 meter 5 section ZZ-fold (33X-5ZZ)

Concrete Line Pumps

When you’re working on a job site that calls for horizontal pumping, concrete line pumps offer superior flexibility and control. Concrete line pumps are ideal for residential projects that require maneuvering around tight places, such as swimming pools and driveways. If your business works on primarily residential jobs or projects that require precise control of concrete pouring, a line pump is a perfect machine for you.

Concrete line pumps can include:

Essential Concrete Pouring Tools List

Once the concrete is poured, you need tools to help the concrete reach its full potential. The following pieces of concrete pouring equipment are used to improve the appearance of concrete:

- Kneeling boards: Kneeling boards support your weight when you’re working on wet concrete so you can fluidly move along the slab’s surface and perfect your hand troweling work.

- Trowels: Trowels allow you to smooth your concrete by hand and clean up the details of your project. Hand trowels are great for perfecting small areas, while power trowels are ideal for larger projects.

- Screeds: With a screed, you can smooth concrete even after it’s been poured by scraping the excess off of the top. Screeds come in a variety of specifications and standardized sizes.

- Concrete floats: Concrete floats are wide-bladed tools designed for use after a screed has already filled in concrete gaps and leveled ridges. There are two main types of concrete floats — bull floats and magnesium floats. Bull floats are used for leveling ridges, while magnesium floats are reserved for smoothing slab edges and smaller slab finishing.

- Thermo-hygrometer: When you need to monitor the relative humidity and speed up drying time, consider investing in a thermo-hygrometer.

Concrete Finishing Tools

Concrete finishing tools allow you to create impressive finishes and ensure your concrete dries correctly. The following concrete finishing tools can help you complete your project:

- Brooms: Traditionally, brooms are used for finishing concrete slabs. By drawing a broom across your almost-dried concrete, you can create a slightly ridged surface that improves slip resistance.

- Grinders: If there’s excess moisture trapped inside your concrete, a grinder can help get it out.

- Power drills and hammer drills: Drills are essential for placing anchors in concrete to prepare the site for attachments. Drills are also great for testing relative humidity as the concrete dries and breaking up concrete when you need to prepare for installation.

- Moisture retardant: Moisture retardants stop moisture from invading finished concrete slabs. Simply install one below or on your grade slabs to stop water problems before they start.

- Relative humidity (RH) test kits: When you need to test relative humidity below the surface level, consider investing in a relative humidity test kit. These kits provide you with an accurate reading of your drying slab’s internal condition and can help you prevent issues related to moisture.

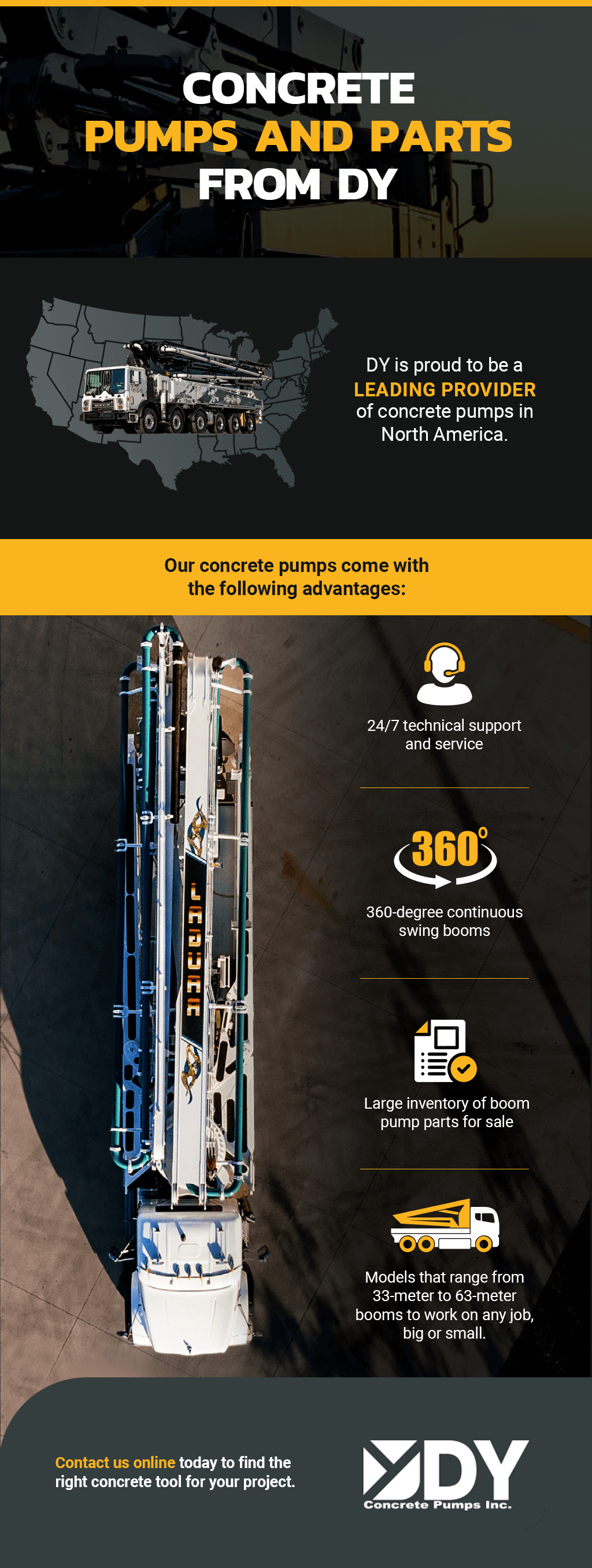

Concrete Pumps and Parts From DY Concrete Pumps

DY is proud to be the leading provider of 360-degree continuous rotating rolls and Z-type booms in the United States. All of our pumps are manufactured from high-quality steel and made using the power of robotic welding to eliminate the chance of human error. In addition to our new concrete pumps and parts, we also offer used concrete equipment and concrete pump repair. Our concrete pumps come with the following advantages:

- 24/7 technical support and service

- Increased durability thanks to robotic welding

- Large variety of boom pump parts for sale

- Roll, fold and Z-type booms for residential and commercial applications

Contact us online today to find the right concrete tool for your project.

1-844-397-8677

1-844-397-8677